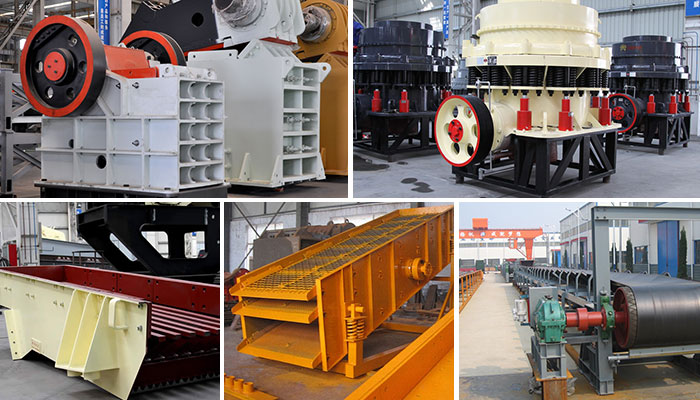

Relative machine:jaw crusher,cone crusher,feeder,belt conveyor

Granite is an igneous rock formed by the formation of magma below the surface. The main components are feldspar, quartz and mica, but there are other components such as silica, alumina, calcium oxide, magnesium oxide and ferric oxide. Wait. Due to its complex composition, it has a wide variety. According to the minerals contained, it can be divided into black granite, muscovite granite, etc.; according to the structure, it can be divided into fine granite, medium granite, coarse granite, porphyry granite, etc.; According to the secondary minerals contained, it can be divided into cassiterite-containing granite and strontium-bearing iron ore..

Introduction to the granite production line:

The granite production line equipment is mainly composed of vibrating feeder, jaw crusher, cone crusher, vibrating screen and belt conveyor. The output is generally 50-800t/h. In order to meet the different processing needs of customers, it can be equipped with sand making and dust removal equipment.

Pre:RETURN LIST

write down your requirement and contact details in the following form to get the latest price of this product within one day!