Size:1.5-11(kW)

Capacity:10~280 t/h

Material:Magnetic separators are widely used in mining, timber, kiln, chemical, food and other industries.

Application: manganese ore, magnetite, pyrrhotite, roasting ore, ilmenite, erythrite, etc.

Magnetic separator is one of the most widely used and versatile models in the industry. .

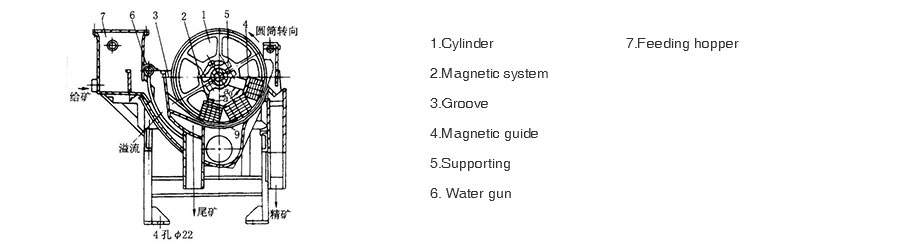

In the magnetic separation process, after the slurry flows into the tank, the ore particles appear loosely into the tank to the mining area. Under the action of the magnetic separator, the magnetic ore particles are combined into a "magnet" or "magnetic flux", which is moved toward the magnetic pole by the action of the magnetic force, thereby being adsorbed on the cylinder. The poles of the magnetic poles are alternately arranged in the direction of rotation of the cylinder. Magnetic agitation occurs due to the alternating magnetic poles, and non-magnetic minerals such as gangues entrained in "magnetic groups" or "magnetic chains" fall off during the flipping, and are eventually attracted to the "magnet" or "magnetic" on the surface of the cylinder. The chain is the concentrate. The concentrate is transferred to the weakest part of the magnetic system at the edge of the magnetic system, and is discharged into the concentrate tank under the action of the flushing water jet discharged from the unloading water pipe; the non-magnetic or weak magnetic mineral is left in the slurry and discharged out of the tank with the slurry. That is the tailings.

| Type | Bore diameter(mm) | Tube length(mm) | Cylinder speed(r/min) | Feed(mm) | capacity(t/h) | power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

write down your requirement and contact details in the following form to get the latest price of this product within one day!