Size:≤1500mm

Capacity:1-2200t/h

Material:Various types of ore crushing, construction waste crushing treatment, concrete mixing station application, etc.

Application: Limestone, hematite, limonite, steel slag, manganese ore, etc

Manganese ore is more common in anhydrous and water-containing manganese oxide and manganese carbonate..

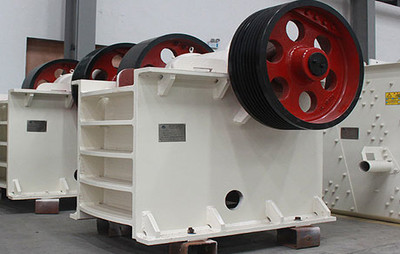

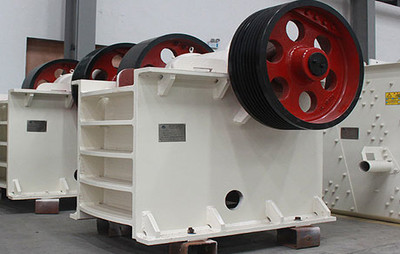

The manganese crusher process mainly includes three processes of crushing, grinding and beneficiation. Generally, the ore is crushed to 6~0mm or 10~0mm, and then grouped, the coarse level is eliminated, and the fine level is sent to the shaker. At present, the commonly used crushing equipment is a jaw crusher. After the crushed manganese ore is milled out of the specifications required in various fields by a pendulum mill, the beneficiation process is carried out using a suitable beneficiation process.

The first stage: crushing and screening - three sections of closed circuit broken

The bulk manganese ore is uniformly sent to the jaw crusher or the mobile jaw crusher by the vibrating feeder for coarse crushing; the coarsely crushed manganese ore is sieved by the vibrating screen and sent by the belt conveyor. The single-cylinder hydraulic cone crusher is used for medium crushing; the crushed manganese ore material is sent to a multi-cylinder hydraulic cone crusher for fine crushing;

| type | feeder (mm) |

capacity (t/h) |

power (kw) |

weight (t) |

size (mm) |

| PE-150×250 | 125 | 20-25 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 180 | 25-30 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 180 | 30-35 | 4P 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 210 | 35-40 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 340 | 40-50 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 425 | 50-110 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 500 | 80-240 | 6P 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 500 | 50-160 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 630 | 110-320 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 640 | 130-330 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 650 | 150-336 | 8P 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 660 | 190-336 | 8P 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 685 | 230-390 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 750 | 220-380 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 850 | 315-500 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1020 | 400-800 | 6P 160-220 | 100.9 | 4200×3300×3500 |

Pre:Granite crusher

write down your requirement and contact details in the following form to get the latest price of this product within one day!