Sand production plant Introduction

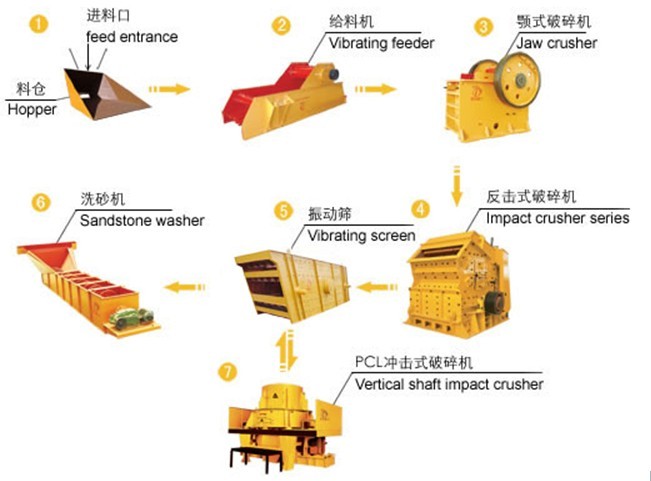

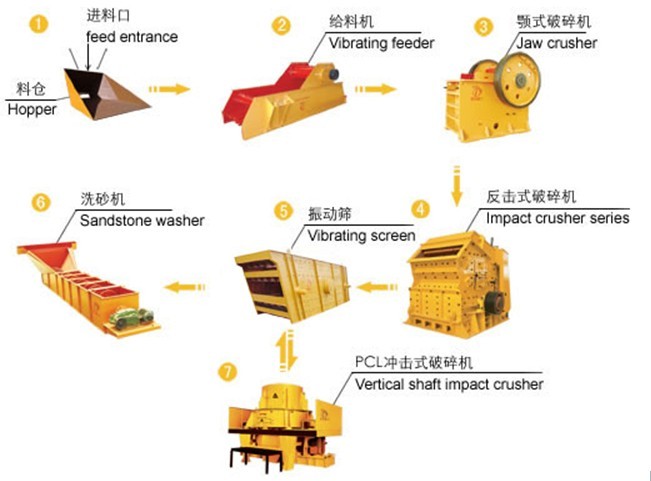

Components: vibrating feeder, jaw crusher, sand making machine (straight through impact crusher), vibrating screen, sand washing machine, belt conveyor, centralized electric control, etc..

Sand production plant working principle

Sand production line usually consists of vibrating feeder, jaw crusher, sand making machine (straight through impact crusher), vibrating screen, sand washing machine, belt conveyor, centralized electric control and other equipment.

Sand production line process:

The stone material is evenly sent to the jaw crusher for rough breaking by the vibrating feeder. The coarsely broken material is sent to the fine jaw crusher or the impact crusher for crushing again. The crushed material is sent into the vibration by the belt conveyor. The sieve is sieved to meet the grain size of the sand making machine, and the stone sand machine is used for sand making. The returning fine crusher (impact crusher) that does not meet the requirements is re-crushed, and the stone from the sand making machine is again Entering into the vibrating screen for screening, screening out the sand that meets the requirements, and entering the sand washing machine for cleaning. After cleaning, it is transported by the finished conveyor belt, which is the finished product; the sand and gravel mixture that does not meet the requirements is sent to the sand making machine for crushing again. The production line finally forms a two-stage closed loop, and various configurations can be performed according to the needs of the user.

.

Technical Parameters

Sand production line advantages:

1. The technical and intelligent processing of the rough and artificial sand and gravel processing field requires less personnel and is more convenient for the user's production and operation.

2. The dry production method is adopted. The materials are stored in the cement storage system, and multiple dust collectors are arranged. The dust is less in the production process and the noise is low. The sand production meets the national environmental protection standards.

3. The first-stage crushing intermediate material warehouse is large enough to separate the first-stage crushing process and the subsequent-stage process, which can be segmented according to the low-valley electricity and weather conditions, and the system command is flexible.

4, high degree of automation, strong processing capacity, the production mechanism of sand type is good, the particles are uniform, the level is reasonable, in line with the national building sand standards.