Size:250-700mm

Capacity:20-700tph

Material:Production of artificial sand and gravel in various ore crushing, railway, highway and construction industries, gravel yard, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Application: Granite, limestone, concrete, etc.

The impact crusher has a novel design principle, adopts a new concept crushing technology, can meet the crushing of different material specifications, and has low unit power consumption. .

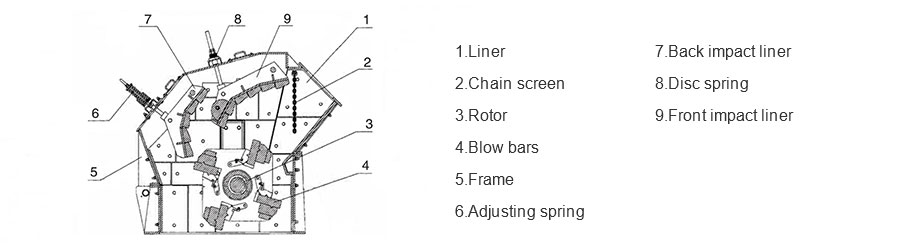

Impact crusher utilizes the impact energy to crush materials. Under the drive of motor, the rotor, with the blow bars, keeps in the high-speed rotation. When the materials fall into the affecting area of rotor, They will be stroke by blow bars and be thrown to the impact devices. Then the materials are rebounded to the working area of rotor for crushing again. The high speed forces the material to rebound from the impact liner to the area where the blow bar effects until they have been crushed to the required size. The gap between the impact rack and the rotor can be adjusted to change the size and shape of the finished product.

| Model | Specification (mm) |

Feed opening (mm) |

Max. feeding size (mm) |

Capacity (tph) |

Power (kW) |

Weight (t) |

| PF-1007 | Φ1000×700 | 400X730 | 250 | 20-70 | 37-55 | 9 |

| PF-1010 | Φ1000X1050 | 400X1080 | 300 | 50-90 | 55-75 | 15 |

| PF-1210 | Φ1250X105 | 400X1080 | 300 | 70-130 | 110 | 17 |

| PF-1214 | Φ1250X1400 | 400X1430 | 300 | 100-180 | 132 | 22 |

| PF-1315 | Φ1320X1500 | 860X1520 | 350 | 130-250 | 200 | 26 |

| PF-1520 | Φ1500X2000 | 960X2020 | 700 | 300-500 | 400-440 | 45 |

| PF-1820 | Φ1800X2000 | 1600X2020 | 700 | 500-700 | 630-710 | 65 |

Pre:Hammer Crusher

write down your requirement and contact details in the following form to get the latest price of this product within one day!