Size:125mm~750mm

Capacity:5-800tph

Material:Widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries

Application: :Limestone, shale, calcium carbide, carbide slag, bluestone, basalt, river pebble, copper, ore, etc.

The jaw crusher is used for crushing coarse, medium and fine crushing of various ores and rocks with compressive strength between 147 and 245 MPa. It has large crushing ratio, uniform product size, simple structure, reliable operation, simple maintenance and low operating cost..

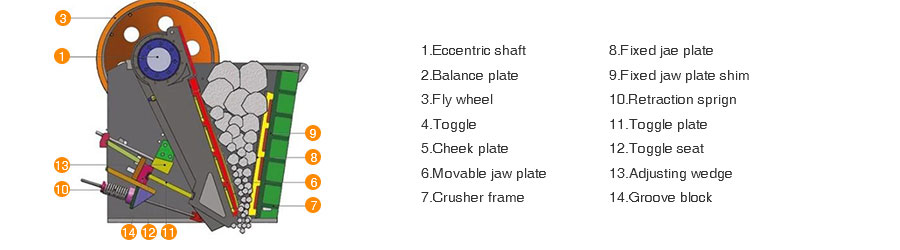

The cymbal is suspended on the mandrel and can be swung left and right. When the eccentric shaft rotates, the connecting rod reciprocates up and down, and the two thrust plates are also driven to reciprocate, thereby pushing the movable cymbal to reciprocate left and right to achieve crushing and unloading. This type of crusher adopts a crank double-bar linkage mechanism. Although there is a large crushing reaction force on the moving jaw, but its eccentric shaft and connecting rod are not stressed, so the industrial is mostly made into a mainframe and a medium-sized machine. To break the hard material. In addition, when the crusher is working, the movement track of each point on the moving jaw is an arc centered on the mandrel, and the radius of the arc is equal to the distance from the point to the axis, the upper end arc is small, and the lower end arc is large. The crushing efficiency is low, and the crushing ratio is generally 3-6. Because of the simple movement track, it is called a simple swing jaw crusher.

| Model | Feeding opening(mm) | Max. feeding size (mm) | Adjustable discharge opening (mm) | Capacity (tph) | Power (kW) | Weight (t) |

| PE-250x400 | 250x400 | 210 | 20-80 | 5--20 | 15 | 2.8 |

| PE-400x600 | 400x600 | 340 | 40-100 | 16-60 | 30 | 7 |

| PE-500x750 | 500x750 | 425 | 50-100 | 40-110 | 55 | 12 |

| PE-600x900 | 600x900 | 500 | 65-160 | 90-180 | 55 | 17 |

| PE-750x1060 | 750x1060 | 630 | 80-140 | 110-320 | 110 | 29 |

| PE-900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 110-132 | 58 |

| PE-1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 |

| PEX-150x750 | 150x750 | 120 | 18-48 | 8--25 | 15 | 3.5 |

| PEX-250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 |

| PEX-250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 37-45 | 8.52 |

| PEX-300x1300 | 300x1300 | 250 | 20-90 | 10-65 | 75 | 13.5 |

Pre:RETURN LIST

Next:Cone crusher

write down your requirement and contact details in the following form to get the latest price of this product within one day!