Size:

Capacity:

Material:

Application:

The iron ore crushing production line, which contains iron elements that can be economically utilized, is called iron ore. There are many types of iron ore, and the main ironmaking products are magnetite (Fe3O4), hematite (Fe2O3) and siderite (FeCO3)..

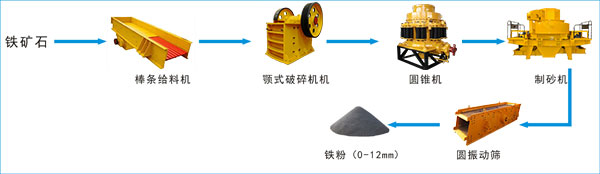

The iron ore crushing plant generally uses a coarse, medium and fine broken three-stage crushing process to break the iron ore. The coarse and broken multi-purpose jaw crusher uses a cone crusher for medium and fine crushing. Through the coarse ore, it is then finely divided into fine particles suitable for entering the ball mill.

The iron ore is uniformly sent to the jaw crusher by the vibrating feeder for coarse breaking. The coarsely broken material is sent by the belt conveyor to the coarse crushed cone for further crushing, and the crushed material is transported to the vibrating screen. The material that has been sieved to meet the particle size requirements of the finished product is transported to the finished product pile through the belt conveyor; the material that does not meet the particle size requirements of the finished product is returned from the vibrating screen to the broken or finely divided cone to form a closed loop. Finished product granularity can be combined and graded according to user needs.

Next:Crush sand plant

write down your requirement and contact details in the following form to get the latest price of this product within one day!