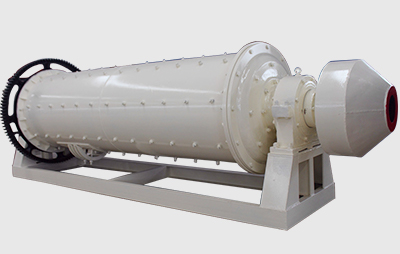

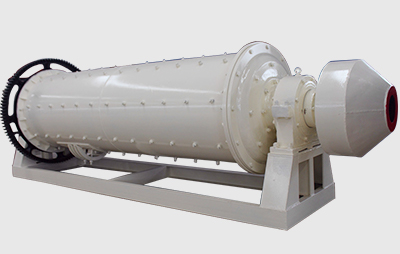

Size:30-1250(kW)

Capacity:0.17-100tph

Material:

Application: silicate products, new building materials, refractory materials, fertilizer.

A high efficiency and energy saving ball mill with rolling bearing..

The materials are evenly conveyed from the feeding device to the first cabin of through the feeding hollow shaft. Inside the first cabin, there are stepped or ripple liners installed and different-sized steel balls placed. When the cylinder rotates, the balls are lifted up under the effect of centrifugal force, and cascade down from near the top of the cylinder. In doing so, the materials are reduced in size by impact and grinding. Then, going through the monolayer welt, coarse materials enter into the second cabin lined with plane liners and placed with steel balls. What needs to be noted is that it is exactly at the second cabin that materials get further grinding until they meet the required particle size. When powdery materials discharge from the grid plate, the operation of grinding comes to an end.

.| Model | Cylinder speed(r/min) | Ball load(t) | Feed size(mm) | Discharge size(mm) | Capacity(tph) | Weight of main engine (kW) | Weight(t) |

| 1200x2400 | 36 | 3 | ≤25 | 0.074-0.6 | 1.4-2.8 | 30 | 11.4 |

| 1200x3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-3 | 37 | 12.1 |

| 1200x4500 | 32.6 | 5 | ≤25 | 0.074-0.4 | 1.83-3.9 | 55 | 13.1 |

| 1500x4500 | 27 | 11 | ≤25 | 0.074-0.4 | 4.8-11 | 90-110 | 199 |

| 1500x5700 | 28 | 12 | ≤25 | 0.074-0.4 | 5--16 | 130 | 23.4 |

| 1830x2400 | 25.4 | 10 | ≤25 | 0.074-0.4 | 4--10 | 130 | 23.7 |

| 1830x3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4.5-10.5 | 130 | 26.6 |

| 1830x4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 68-11.5 | 155 | 30.4 |

| 1830x6000 | 24.1 | 21 | ≤25 | 0.074-0.4 | 7--12 | 210 | 32.3 |

| 1830x7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.8-13.8 | 245 | 34.2 |

| 2100x3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 5.8-14 | 155 | 32.3 |

| 2100x4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 9.5-32 | 245 | 40 |

| 2100x6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 50.3 |

| 2100x7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 51.3 |

| 2100x7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 53.2 |

| 2400x3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7.8-18 | 245 | 51.3 |

| 2400x4500 | 21 | 30 | ≤25 | 0.074-0.4 | 13.7-28 | 320 | 64.7 |

| 2700x4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 15-28 | 400 | 89 |

| 2700x4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 16.5-36 | 430 | 97 |

| 3200x4500 | 18 | 65 | ≤25 | 0.074-0.4 | 24-49 | 800 | 130.5 |

| 3600x4500 | 17.8 | 88 | ≤25 | 0.074-0.4 | 29-65 | 1250 | 165 |

Pre:RETURN LIST

Next:Rod Mill

write down your requirement and contact details in the following form to get the latest price of this product within one day!