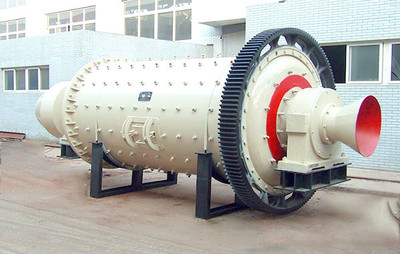

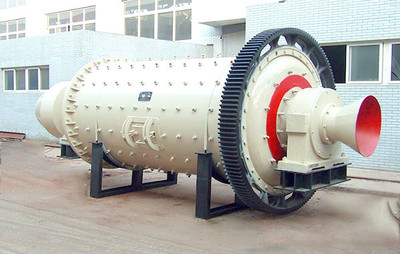

Size:15-22KW

Capacity:3-8tph

Material:

Application: It is widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal dressings and glass ceramics and other production industries.

The dry grinding mill is the key equipment for crushing the material after it has been crushed. It is widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal dressings and glass ceramics and other production industries..

working principle:

The dry grinding mill is a horizontal cylindrical rotating device, external gear transmission, two bins, and a lattice ball mill. The material is uniformly fed into the first chamber of the mill by the feeding device through the hollow shaft of the feeding material. The chamber has stepped lining or corrugated lining, which is filled with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel ball to a certain height. After falling, it will hit and grind the material. After the material reaches the rough grinding in the first bin, it enters the second bin through the single-layer partition plate. The bin is embedded with a flat liner with steel balls inside to further grind the material. The powder is discharged through the discharge raft to complete the grinding operation..

Pre:Cement ball mill

Next:RETURN LIST

write down your requirement and contact details in the following form to get the latest price of this product within one day!