Size:

Capacity:280t/h

Material:

Application:

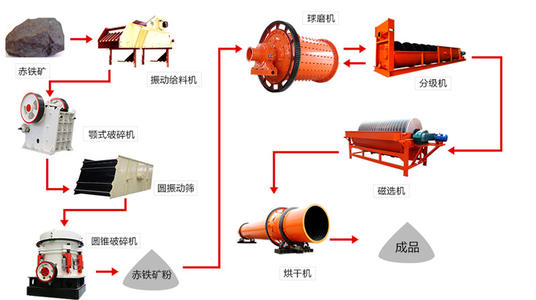

Hematite crushing plant is a dry-wet combined beneficiation magnetic separation process method for magnetite. It can be processed according to the nature of the red iron mineral material and the special working environment..

Production Process

1, broken, sieved. The mined hematite is uniformly and continuously fed from the feeder to the jaw crusher, and preliminary crushing is carried out in the jaw crusher; the hematite which is initially crushed enters the vibrating screen by the jaw crusher and is sieved. Material, producing a sieve and a sieve;

2, grinding, classification. The sieved good hematite mineral material is sent to the ball mill from the vibrating screen via the hoist and the feeder to be pulverized and ground again; the ground hematite fine material enters the classifier and precipitates in the liquid due to the specific gravity of the material. Different principles, washing and grading materials;

3, magnetic separation, drying. After the materials washed and classified in the classifier enter the magnetic separator, the magnetic materials are separated due to the different magnetization coefficients of the mixture; the separated materials contain a large amount of water, and then are dried by the dryer. Dry work to get a dry finished product..

write down your requirement and contact details in the following form to get the latest price of this product within one day!