What is the process of the wet sand plant?

2019-03-13 09:14:17

If you are looking for related products or have any other questions, you can email us or click the button below to chat with us online!

Solution

Jaw crusher + Impact crusher

This production line is applicable to produce sand with all kinds of raw materials, which is of compact and reasonable structure and high efficiency. It adopts vertical shaft impact crusher as sand making machine. In the following flow chart, the sand washer removes the silt and dust to make the final product clean and improve the quality. The final product, artificial sand, is in ideal shape and the size gradation can be adjusted.

This production line is applicable to produce sand with all kinds of raw materials, which is of compact and reasonable structure and high efficiency. It adopts vertical shaft impact crusher as sand making machine. In the following flow chart, the sand washer removes the silt and dust to make the final product clean and improve the quality. The final product, artificial sand, is in ideal shape and the size gradation can be adjusted.

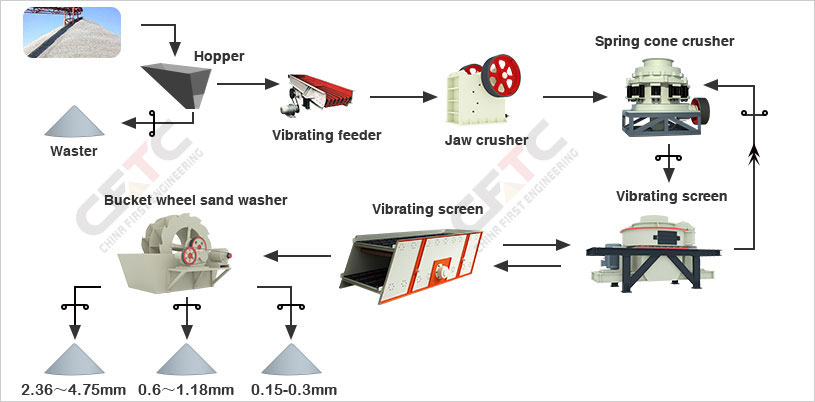

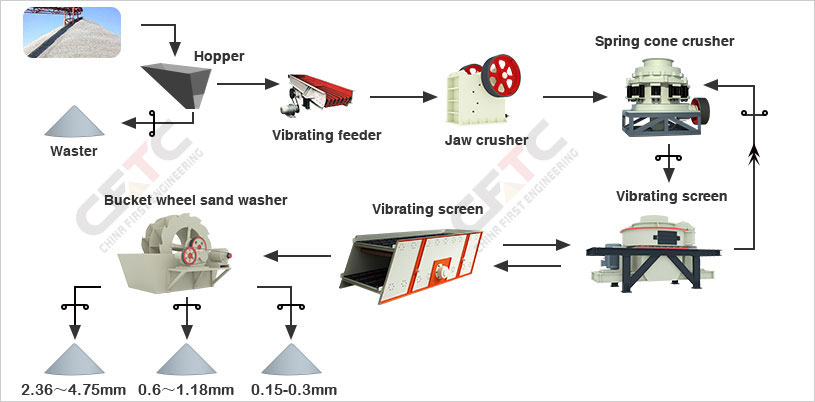

For the wet sand production line process, the common ones are divided into four stages: “coarse-medium-fine-sand-sand-sand-washing”. The specific process steps are as follows:

a. Primary crushing: large raw ore is evenly fed into the jaw crusher through the vibrating feeder;

b. Intermediate fine crushing: the crushed stone after the initial crushing is evenly and orderly sent to the inner part of the impact crusher by the belt conveyor, and is reasonably sieved by the circular vibrating screen, and the larger granular stone is returned to the counter-break and broken again;

c. Sand making: The stone that has passed the screening will be sent to the sand making machine for fine crushing and sand making. The circular vibrating screen will also be divided into different specifications of fine sand. The unqualified products will be returned to the sand making machine and crushed again;

d. Washing sand dehydration: the finished fine sand that has been sieved and qualified, will be sent to the sand washing machine for efficient cleaning and impurity removal, and can be used as the final finished sand, which is naturally dried and sent to the storage bin.